- Home

- About Us

- Cooper Gensets

- Services

- Exhaust Piping, Cladding, MS strucutire design and fabrication

- Design and supply of HT LT PCC and MCC panel

- HT LT cabling work

- Design and installation of piping projects and construction of diesel yard for diesel stock in high volume

- PESO Lincense for disel storage/ explosive

- Design Installation of Internal House wiring, garden and showrooms

- Supply & Installation of Industrial shed wiring / Building wiring

- Automation in fuel supply and piping heat insulation

- Allied Civil work Activity

- Concertina coil compound

- Project

- Contact Us

HOME< PROJECT < FUEL LEAK DETECTION SYSTEM FOR DG SETS

FUEL LEAK DETECTION SYSTEM FOR DG SETS

Supply and Installation of ELSA make Fuel Leak detection system.

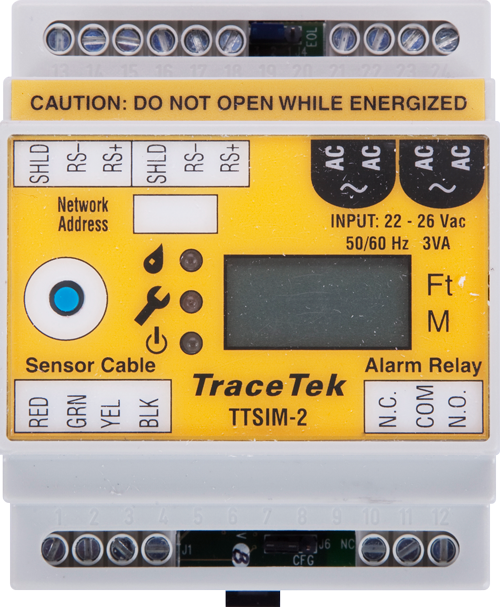

Supply and installation of TraceTek make fuel leak detection system.

Design, engineering, supply, installation, inspection, testing and commissioning of complete Leak Detection system complete with all accessories/devices/software and hardware required for making the system complete as per design intent as per below,

Supply, Installation, Testing & Commissioning of Addressable Main Fuel Leak Detection Panel with Touch Screen Display networkable on RS 485 with Fuel Leak Detection Modules.

It give pin point of leak distance in Meters and cable fault conditions of each networked modules.

Panel is with BACNET Over IP or Modbus Ober IP output for BMS monitoring.

Power Supply shall be 230 VAC input with Batteries and Battery Charger.

Supply, Installation, Testing & Commissioning of Sensor Interface Module, with capability to extend one sounder output and connect upto 150 mts of sensing Cable with 32 such Modules connectivity to the Main Panel. Module to be enclosed in NEMA 4X enclosures with transparent cover for easy viewing.

Supply and Installation of ELSA make Fuel Leak detection system.

Supply and installation of TraceTek make fuel leak detection system.

A Fuel Leak Detection system (FLD) locating system provides distributed leak detection and location over long distances and wide areas. A FLD locating circuit consists of a FLD locating module (TTDM-128, TTSIM), sensing cable and/or point sensors, and circuit components (leader cable, jumper cables, end terminations, weighted lengths, and branching connectors) with connectors that allow components of the system to plug together. The weighted length resistor simulates a 4.5 m (15 ft) length of sensing cable. Installed at the boundary between two areas of sensing cable, the weighted length allows the user to clearly identify the area where a leak has occurred. The branching connector enables the sensing cable to be branched. An end termination completes each branch. At the branching connector, the system first counts the sensing cable along the branch (middle connector) to its end termination, before it continues with the main run. Two built-in 4.5 m (15 ft) weighted-length resistors allow the user to clearly identify the leg on which a leak has occurred. Modular Jumper Cable between module and area monitored Modular Leader Cable Sensing Cable Alarm and Locating Module Sensing Cable daisy-chained together to provide as much coverage as needed Modular Branching Connector Tags Hold-Down Clips Modular End Termination (required at end of every branch)